Making bikes is not that hard. Running a frame building business is. Selling bikes, order material, paying bills, cleaning up, and my favorite: accounting. The list goes on of things that are not as fun as making bikes. While I can not help you with any of these things, I can help you make bikes and forks better and faster then you may be making them now.

I have mitered and tacked thousands of bicycles and forks. I first started building bikes at Fat City Cycles in the early nineties and soon after started Independent Fabrication with my friends in 1994. When we started IF we had a blank slate. We could make bikes any way we wanted. For whatever reason I was the one who started making our tools. Maybe because Mike was painting and welding all of the bikes and Lloyd was mitering the job of tool making fell on me. Lloyd and I always joked about wanting to have tools simple enough that we could hire monkeys to do it. It was a joke but had some truth to it. We weren’t interested in fancy things we just wanted our tools to work. We wanted them to be simple, rigid, repeatable and most importantly TRUSTWORTHY. I wanted to be able to be cutting my next set of stays to length and deburring the previous set of stays while mitering new ones. I did not want to have to babysit my machines. When I see pictures of builders with a production mitering jig squinting and resting there hands on the stays while they are being cut they do not trust their tool. As much as we all like to romanticize frame building it is still manufacturing and time is money. The first mitering tools we made were out of aluminum. It was fast and cheap and easy. We soon learned that came with a cost. They didn’t last and cost us time.

As we grew I was lucky enough to be able to spend more time focusing on the process. We tried lots of things, some worked, some didn’t. In the beginning we were doing runs of bikes, anywhere from 2-20 of a stock size at a time. By 1997 the market changed and everyone needed a custom bike. I would spend half my day cutting tubes for custom bikes and the next half making our tools work better for the new reality. I would constantly ask myself what job did I hate to do. If I hated making bridges I would try to figure out how to make them easier and faster. The basic principle behind all my tools has not changed much since then. They may look a bit more polished now but the idea behind each one is the same. I figured out what worked for us and have been focused on improving them ever since. Making bikes is manufacturing and any good tool should be simple, repeatable and trustworthy. Shiny things don’t make your tool better they just make it more expensive.

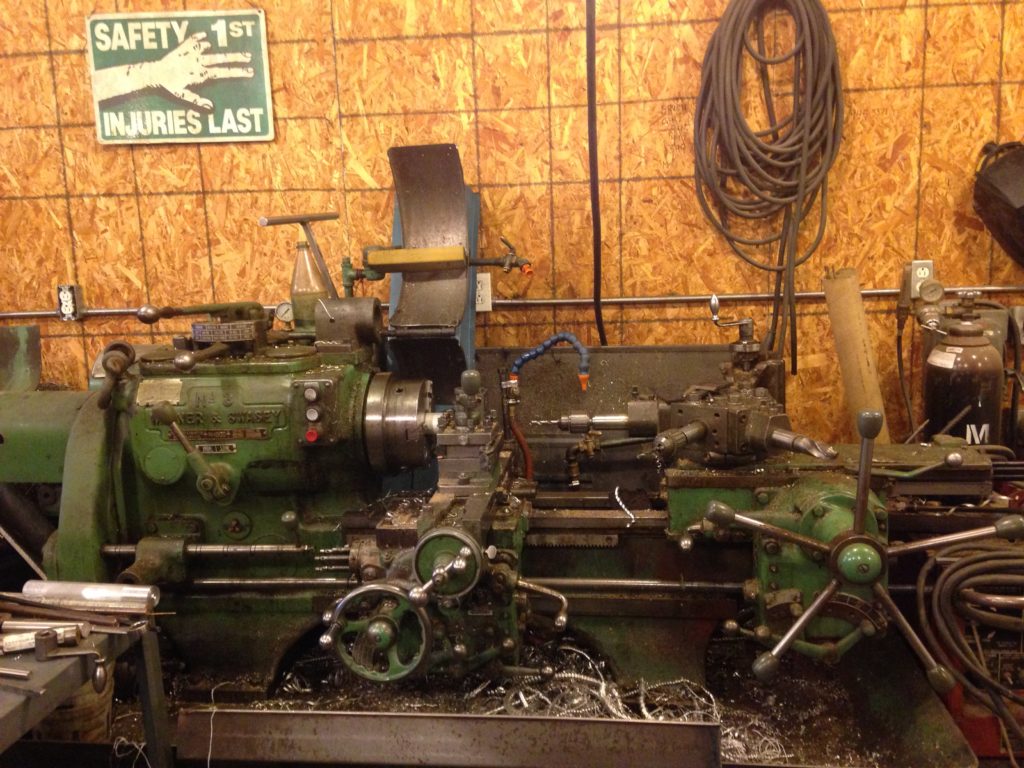

As Sputnik Tool has grown many things have changed with me and with the industry. I no longer build tools on just a Bridgeport and 10″ manual lathe in an small unheated shop connected to my 1840’s cape. I now have a heated shop next to my old house with CNC machines and an incredible Warner and Swasey turret lathe along with lots of other stuff. The industry has changed also. There are a hundred new standards and choices for the builder today. Choices used to be top tube or down tube cable routing, two waterbottles or three and paint. The number of small builders all over the world has exploded also. I am always amazed at the places some of my tooling ends up. Many builders working today build fewer bikes in 2 or 3 years then I used to miter and tack in a week. I am working on wrapping my head around that in how I design and make my tools. While my tools have always offered the most features and been the best value available they were often dismissed as “production tools not made for the small builder”. While I am fine to have my tools described as “production tools” I do not understand why that is not something any builder would not want to take advantage of . My tools are designed to do one job: Make your life easier. Whether you are building 10 bikes a year or 1000 the process is the same and a well designed tool can only help you improve your process.