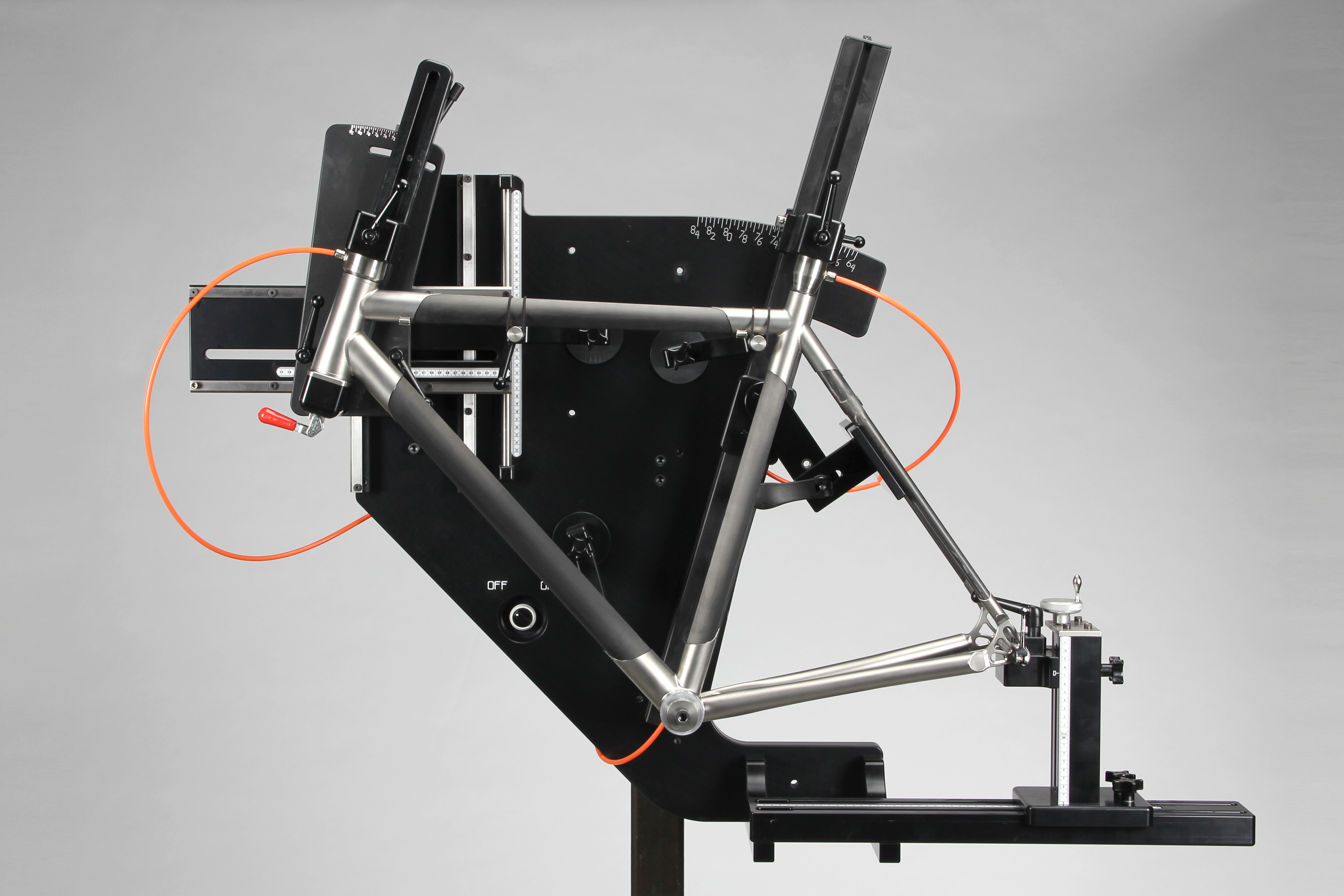

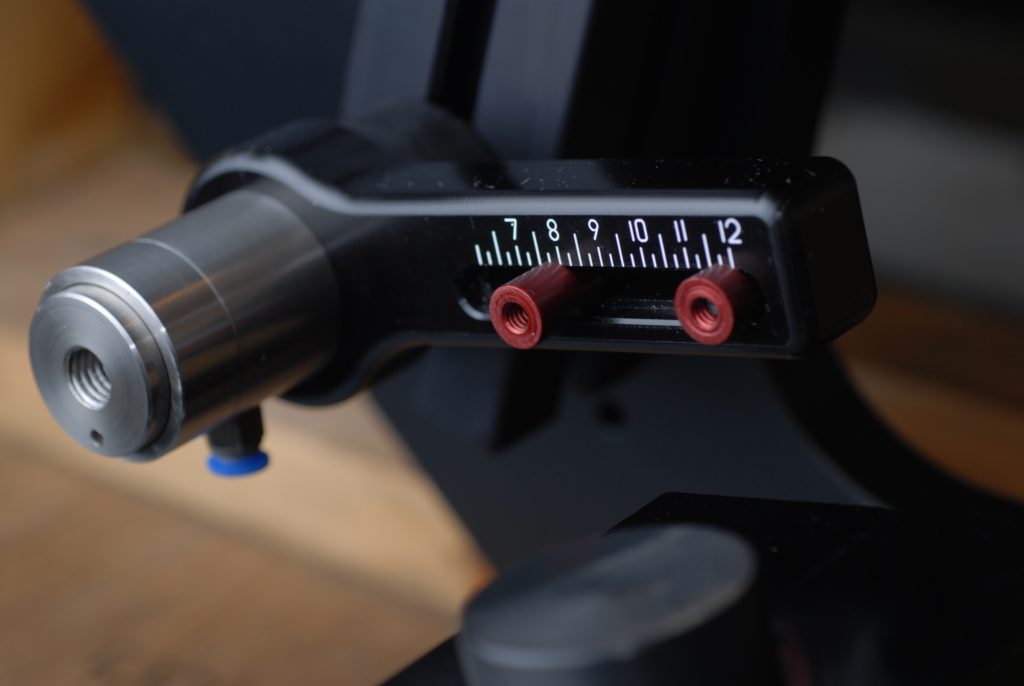

Since the I built the first version of this jig almost 25 years ago I have continually worked to improve upon it every year. I have added a few new features over the last two years that can be added to the stock jig to improve its functionality with some of the new bikes builders are making. The chainring guide mounts on the BB tower and is used to ensure proper clearance between your chainstays and chainrings. Using data available from Shimano and Sram posts can be adjusted to mimic chainring locations giving you greater confidence in achieving proper chainring clearance while maintaining as much tire clearance as possible.

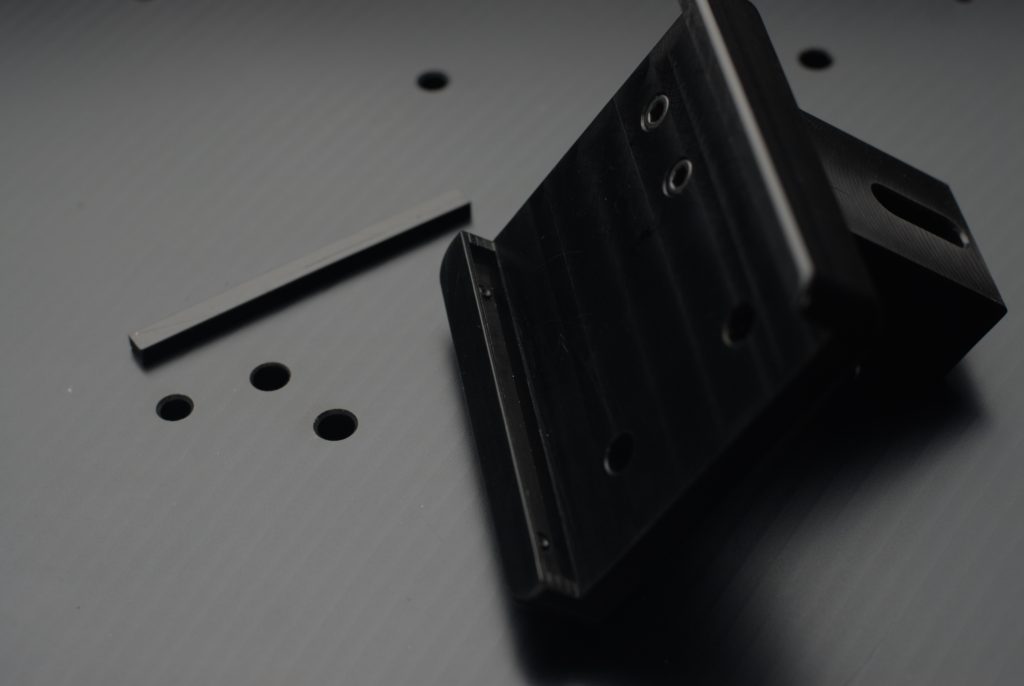

With the advent of bent seat tubes to fit larger tires and allow for shorter chainstays a new seat tube tower has been developed to more easily hold and locate these tubes. By using the offset of the seat tube bend, builders can adjust the tower to hold the seat tube in place while still confidently describing the geometry of the frame.

New for this year I have also added another chainstay plate. This plate mounts near the dropout tower and includes eccentric posts that can be used to hold and locate the chainstays in the proper position at the dropout. This is especially useful with breezer style drops.

The Sputnik Tool frame jig has many other features also not available on other commercially available jigs. On the Sputnik jig all of the tubes including the seat stays and chain stays are supported and held in the proper location. The chain and seat stays are held on flat plates that locate the stays on the same plane and help maintain parallelism. The chain stay plate can also hold different sized pucks to ensure proper tire clearance and symmetry. The down tube and seat tube stand-offs locate the tubes on the BB centerline for repeatability. This eliminates the need to scribe a line on the BB and manually locate the tube on center every time you put it in the jig. The X and Y movement of the head tube assembly is done using linear bearings for smooth stiction free motion with zero play and no racking. The stand-offs for both the head tube and seat tube also have special internal features that eliminate racking which is cause by excessive cantilevering of the components. The tower for the rear drop outs also has rack free motion fore and aft as well as up and down for the BB drop. Eliminating racking and excessive play in the jig is key to allowing you to produce straighter bikes. When all of these features are combined you are allowed to work much faster and a greater degree of confidence.

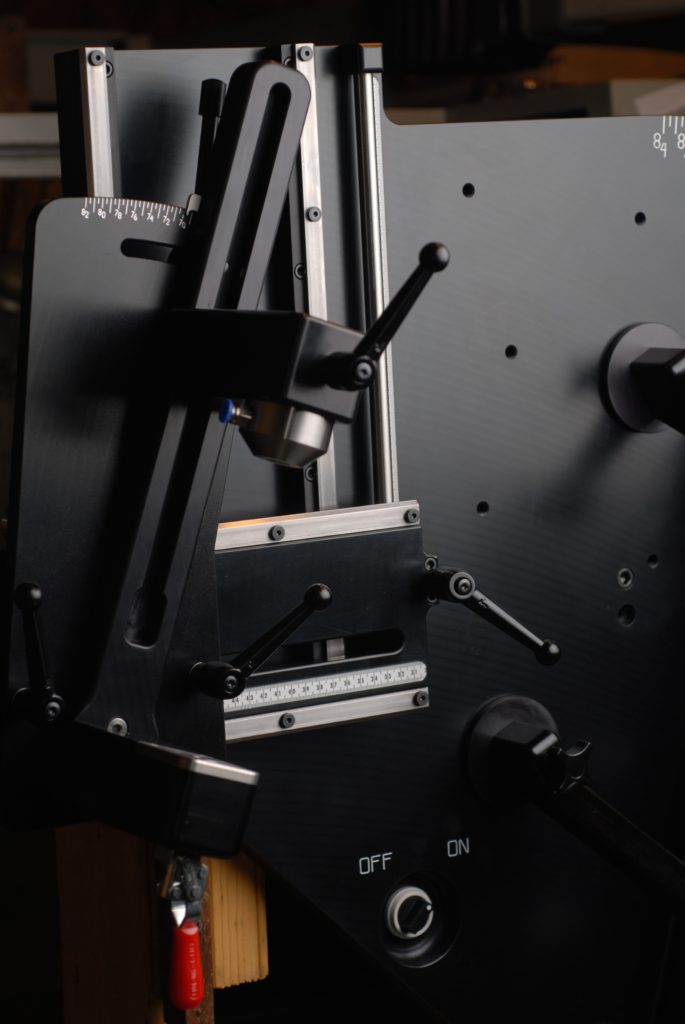

head tube assembly

Seat tube assembly

Precision rails and bearings control HT motion

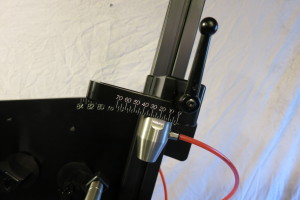

HT vertical lock assembly

Retracting SS puck and HT interface

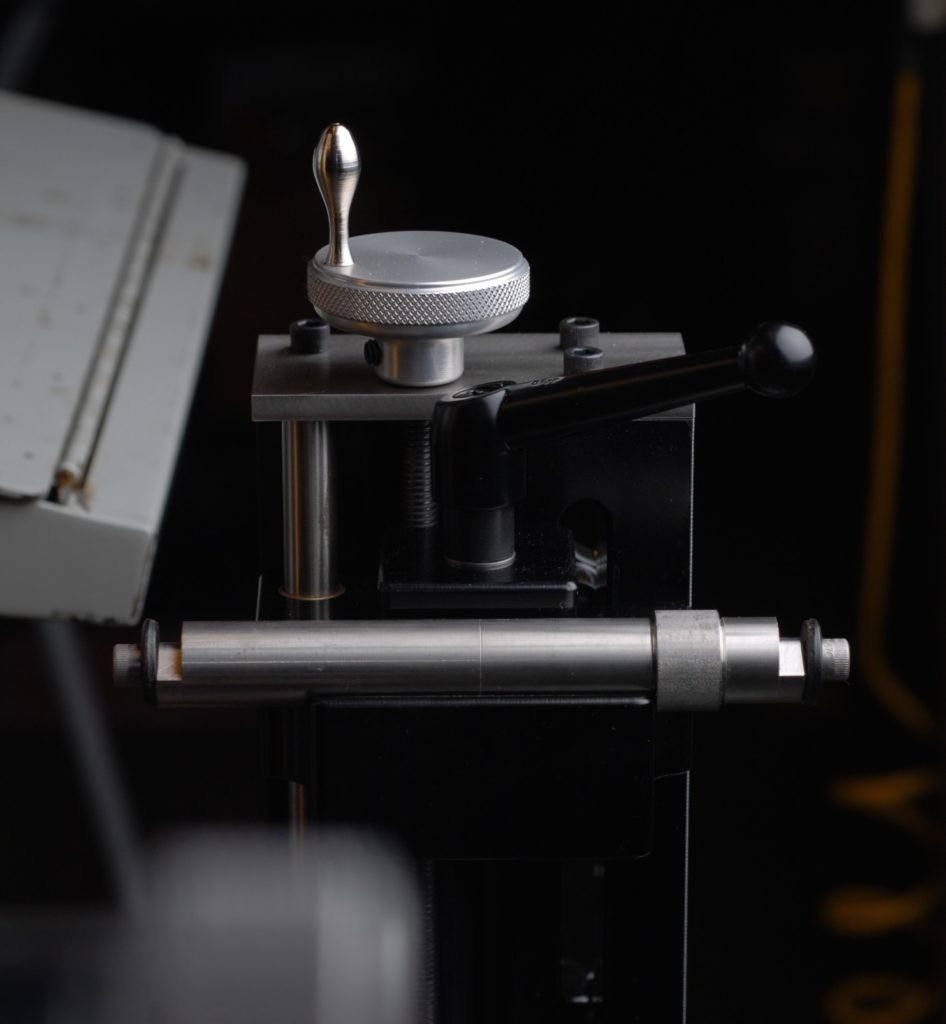

Dropout tower

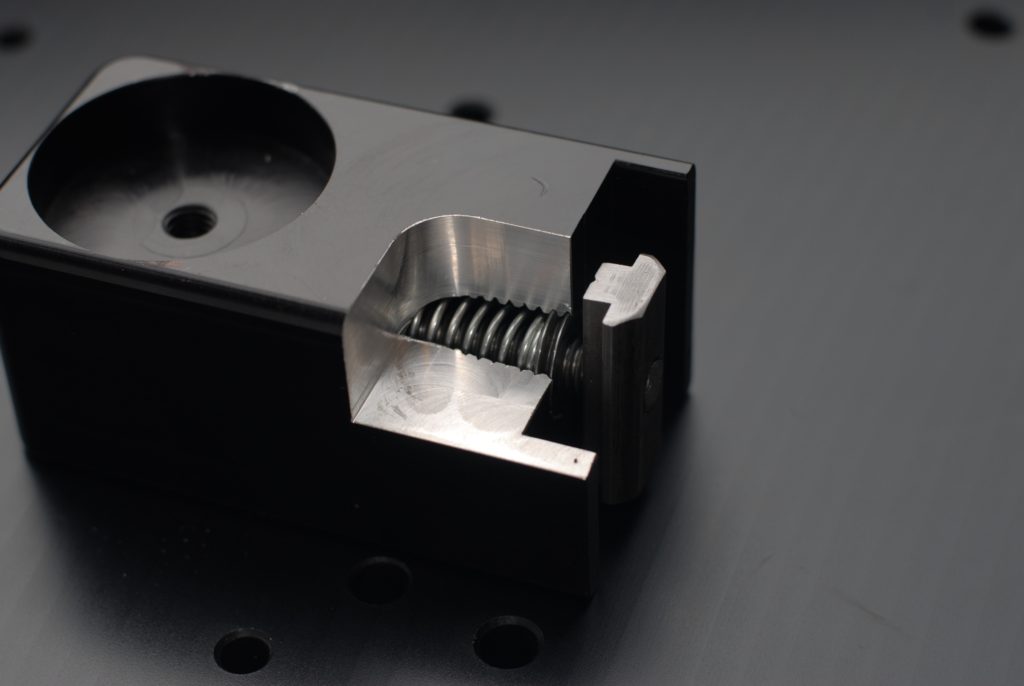

Gibs on slides ensure smooth and precise motion

Chainring checker

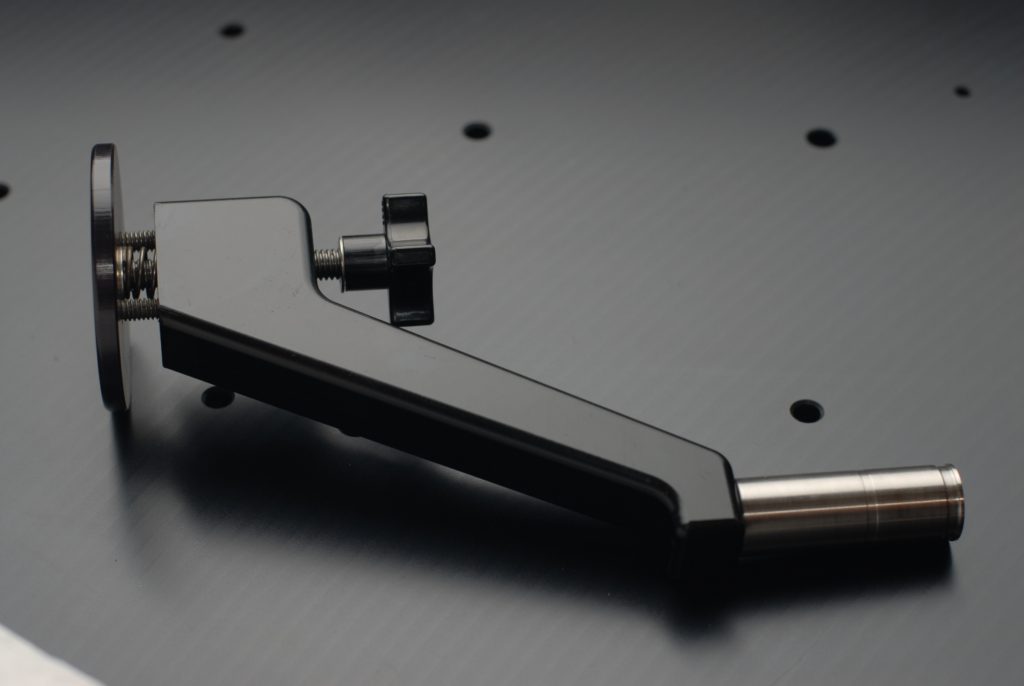

Spring assembly in tube towers allow for smooth 1 handed adjustment

Internal spring keeps towers from falling and racking during travel

BB assembly with seat tube stand off and chainstay puck